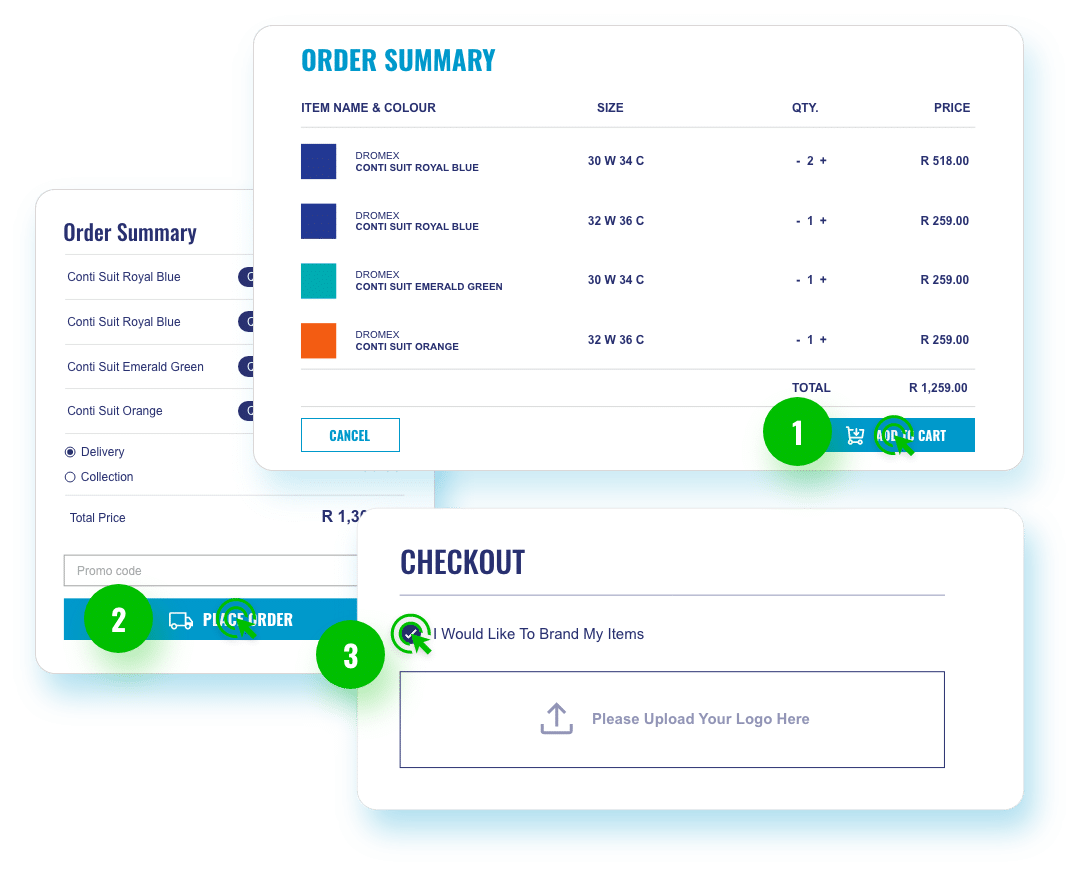

How to Add Branding

Step 1: Construct your order.

Select your items and add them to your cart. Not all items can be branded e.g., gloves, safety boots, eyewear etc. You may complete your entire order in one go.

Step 2: Confirm your order and continue.

Before payment, tick the “I would like to brand my items” checkbox and upload your logo. Fill in some details on where you would like the logo, the size of the logo and any other information you would like to include in the branding.

Step 3: Checkout

Once you have uploaded the logo and checked out, your order would have been paid without branding. One of our friendly sales staff will contact you with a separate quote to brand the items that you purchased and discuss the best branding option, lead times and send through artworks before proceeding.

Types of Branding We Offer

EMBROIDERY

Embroidery is stitched with a computerised embroidery machine using patterns digitised with embroidery software. Artwork must first be digitised, which is the specialised process of converting two-dimensional artwork into stitches. Up to 10 cotton colours may be added to a logo, although fading of colours and exact pantones cannot be matched and the closest cotton thread will be chosen. Ultra-durable and often outlasts the garment. Longer process but the correct choice for the long run.

SCREEN PRINTING

Screen printing is a printing technique whereby a mesh screen is used to transfer ink onto a substrate. This is the most common method of imprinting on promotional items and apparel. Used for large quantity of prints on t-shirts, Conti suits and golfers due to the low cost. Increases in price the more colours the logo has. Not limited on the size of the print. A long lasting and durable type of branding.

SUBLIMATED BADGES

Dye sublimation is a digital printing technology that uses heat and ink transfer to apply an image to the intended substrate. A sublimated badge involves printing an image or logo onto a badge type material and cutting it to shape. This is then stitched onto the garment in the desired location. This type of branding is fast, long lasting and creates a great impression. Often printed initially and then kept for urgent branded jobs as stitching is done on site.

Is sublimation better than screen printing?

When done correctly, both printing methods will produce long-lasting prints that should neither fade nor crack, even with prolonged washing.

While it’s true that both printing methods have their individual benefits, there are a few key factors to consider when trying to decide whether dye sublimation or screen printing is best.

Are sublimation and heat transfer the same thing?

The foremost difference between heat transfer and sublimation is that with sublimation, it is only the ink that transfers onto the material.

With the heat transfer process, there is usually a transfer layer that will be transferred to the material as well.

Setup of the Job

One of the biggest limitations of screen printing is that only a single colour can be applied to the substrate at any one time. There is also the added concern of the alignment of the different layers of colour. As such, screen printing setup times can be extensive when there is more than one colour involved.

On the other hand, with sublimation, there is no need to worry about the alignment of the individual colours as this process will print all of the colours at once. Designs can be more easily customized with this process, as you will only need to change the article work and print out a new transfer for the changes to take effect.

Embroidery also involves quite a large setup; each cotton needs to be threaded and garments need to be framed in the correct position. Once the initial setup has taken place it’s a quick process to run the logo, depending on the stitch count. After embroidery, the garment needs to be cleaned. This is when all the loose threads and backing is removed to reveal a clean and crisp logo.